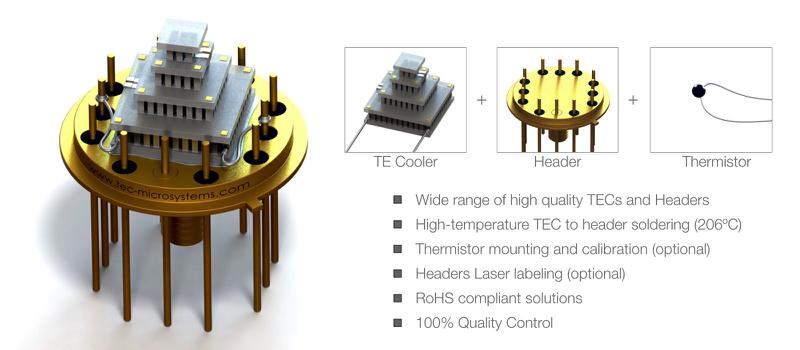

Thermoelectric sub-assemblies TECs on Headers

In a large number of applications thermoelectric modules are incorporated into packages or mounted on headers. Our core competence is to provide a fully tested thermoelectric sub-assembly (TEC mounted on a header), minimizing this way the risk of possible TEC damaging during mounting process for our customers. Our specialists professionally solder the thermoelectric cooler on standard headers / packages or in housings provided by the customer. TECs will undergo testing twice – before and after mounting. This increases the reliability of your final product, saves time and money.

Our service starts from trial volumes for fast prototyping up to high volume production. During product development we analyse the application and provide the most optimal TEC solution.

The term “thermoelectric sub-assembly” means a thermoelectric cooler mounted into standard or customized package. Thermoelectric sub-assembly is a perfect solution for fast and easy integrating into final application. There is a range of industry standard headers and packages, that are usually used with thermoelectric coolers. TEC Microsystems provides the range of thermoelectric solutions based on most common headers and packages. Thermoelectric coolers are mounted by high-quality soldering process with strict QC control. The process is flux-free and made in vacuum environment. All the sub-assemblies pass 100% quality control.

TE SUB-ASSEMBLIES ADVANTAGES

- Reduce risks and expenses on Customer side

- Significant time saving for projects

- Simplify TECs and headers supply issues

- Perfect solution for R&D with trial quantities

TE SUB-ASSEMBLIES KEY FEATURES

- High quality soldering of TECs to headers

- Advanced RoHS high-temperature soldering

- Wide range of manufacturing options

- 100% quality control

One of the smallest TO-style headers with about 1.2 x 1.9mm2 open space for thermoelectric cooler. Ideal for low-power LD applications like VCSEL.

TO-style header with 6 or 8 pins and 3.2×3.2mm2 open space for TE cooler integrating. Common both for LD and detector applications.

One of the most common TO-style headers, optimal for IR- and X-Ray applications. Up to 8.6 x 8.6mm2 open space for TEC integrating. Single- and multistage TEC solutions.

TO-style analog of TO-8 with side flanges for easier mounting. Available space for TEC is around 5 x 5mm2. Suitable for single- and multistage thermoelectric coolers.

Relatively large TO-style header mainly for powerful LD applications. Large contact area for better heat spreading, open space for TEC integrating is about 8x8mm2.

TO-style alternative to TO-3 header with enlarged open space for TE cooler. Up to 12 x 12mm2 open space for thermoelectric cooler integrating.

Large family of flatpack style packages with 10 to 72 pins, optimal for detector arrays or similar application with thermoelectric cooler and large number of pins required.

“Pins down” rectangular packages with a large open area for TEC and up to 72pins. Common solutions for CMOS and CCD detectors with active TE cooling.

Classical High Heat Load (HHL) 9pin packages for laser applications. Suitable for applications with powerful TECs and large amount of heat to spread away.

Analogs of ML06 TECs, single-stage TE coolers with extra 35-40% cooling capacity reserve for DWDM projects. Elongated shape for typical 14pin “Butterfly” or DIL packages.

Customized solutions development, packages and related thermoelectric cooling solutions in accordance to customer requirements. CNC machining services

Special solutions for IR applications. Thermoelectric sub-assembly is additionally equipped with a high-emissivity, thermally uniform emitting surface and a temperature sensor. Provided as hermetically opened OEM sub-assemblies

TEC mounting services in customer packages with RoHS compliant high-temperature soldering and 100% quality control.